SMR Spent Media Rewinder

Home » Products » Filter Media » SMR Spent Media Rewinder

The spent media exiting the filter has traditionally been collected in drums, hoppers and corrugated boxes. This method, however, results in collection containers overflowing with spent media, a dirty work area and a less dense package for collection resulting in higher disposal costs.

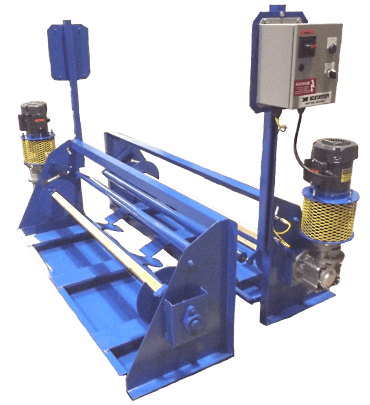

The Filtertech model SMR spent media rewinder solves these issues by rewinding the media onto a roll for easier disposal management.

Mode of Operation

The Filtertech Model SMR and SMR/S Spent Media Rewinders when installed at the discharge end of a media filter automatically rewind the spent media into a tight roll providing a smaller, more dense package for easier disposal. The media rewinder drive motor rewinds the spent media onto a disposable core. During indexing and when the media is not in motion, the drive motor maintains tension on the media between the rewinder and the filter.

The rewinder is electrically connected to the existing filter’s control panel so that the rewinder’s drive motor is automatically activated at the same time as the media drive on the filter. Controls for the rewinder include both manual and automatic operation and can be incorporated into the existing filter control panel or be mounted on a separate panel near the rewinder.

As the spent media is rewound into a tight roll, excess moisture in the media is squeezed out and collected in a drip pan beneath the media roll. Once the spent media roll reaches the desired size for disposal, the spent media is manually cut between the rewinder and the filter. The disposable core is then discarded with the spent media, and a new core is inserted into the rewinder, secured with locking pins. The spent media from the filter is then attached to the disposable core, which is made from standard 2′x4′ lumber.

The Media Rewinder is available in a variety of standard widths and speeds to accommodate all media sizes and can be readily adapted to the majority of existing or new filtration equipment.

For sludges with reclamation value, the media rewinder can be equipped with a sludge separator which incorporates a doctor blade that removes the majority of the sludge from the media and is discarded into a collection hopper included with the unit.

The Filtertech Spent Media Rewinder & Sludge Separator provides for fully automatic rewinding of spent filter media for a variety of filters thus eliminating operator attention and producing a more dense, drier waste for less-costly disposal.