Spent Coolant and Waste Reduction / Minimization

This application is present in companies that are engaged in any metal or non-metal industries that use industrial coolants, water, emulsion and oil for their specific processes.

Many industrial processes generate aqueous based waste streams which require either on-site treatment or off-site disposal. These waste streams quite often are comprised of mostly water and treatment is charged by the gallon for coolant disposal. In addition to this inherent cost, there is ever increasing pressure to reduce the amount of waste generated, disposed of off-site, or discharged to drain.

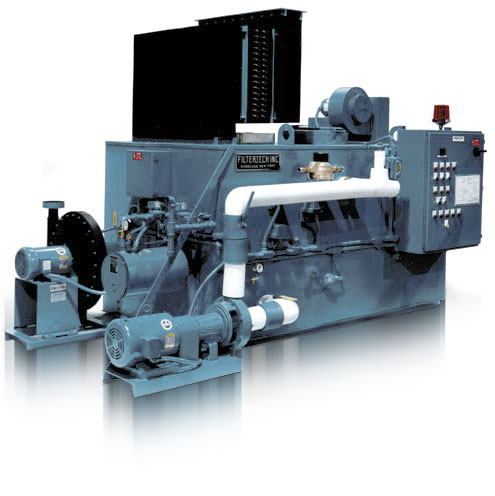

To serve the needs of sustainable manufacturing, with reduced effects on the environment and more efficient use of resources, Filtertech has developed the equipment and systems for proven and reliable results. We serve many applications of waste reduction and minimization.

Waste disposal of any type is very costly, whether hazardous or non-hazardous materials are involved, as it must meet stringent disposal specifications and environmental regulations. In most cases, the quantity of contaminants such as oil and/or dissolved metals in water are very small compared to the amount of water that needs disposal as hazardous waste.

Removing dissolved metals from the water by a Waste Water System makes the water meet the specification for disposal as non-hazardous waste is a cost-reducing benefit.

In the case of emulsion, where a small percentage of oil or lubricant {3-10%} is dissolved in water, the Thermal Emulsion breaker evaporates the water phase of solution and concentrates the oil which can reduce the amount of total waste by up to 90%.