Optical Lens Generation

In the process of optical lens generating, shaping and surfacing, a water-soluble coolant is used to cool and lubricate during lens generation.

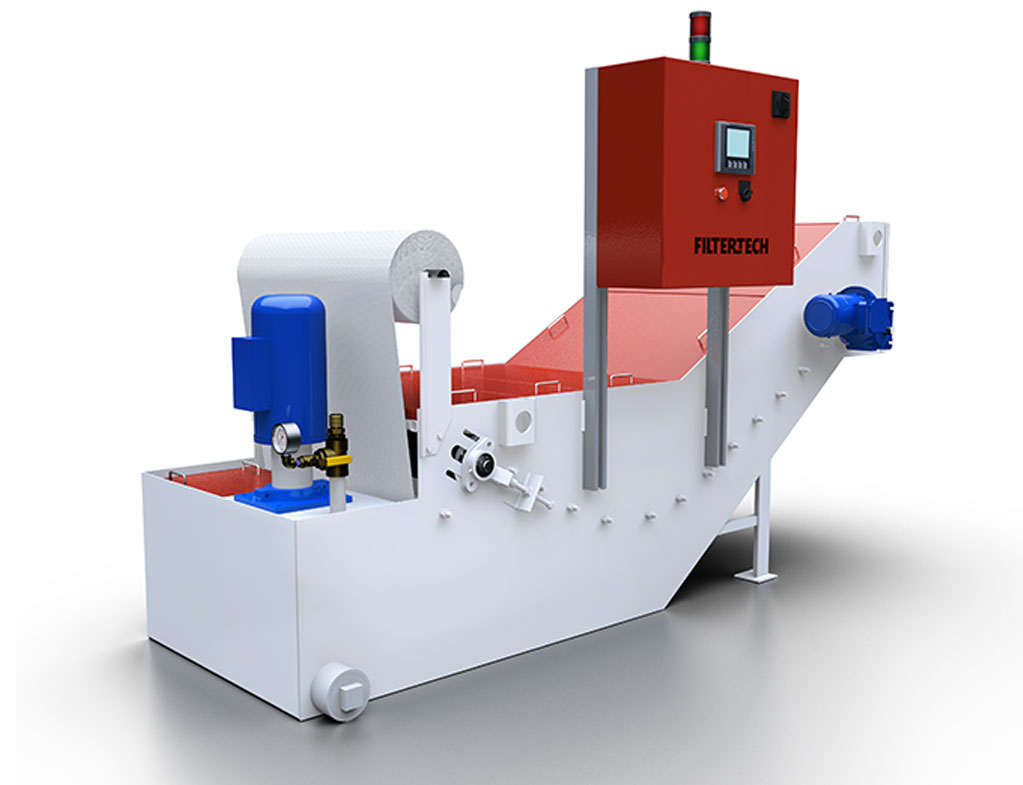

The coolant lubricates and cools the lens during the cutting process. The coolant then contains particulate and contaminants and requires a filter system that uses a gravity or vacuum filter to remove the very large and extremely fine particulate. The filter system will produce very clean coolant that is required for this precision process. Complete system packages include filters, whether it be gravity or vacuum, tanks, briquetters, pumping/transfer stations, wet drum, heat exchangers, guard filters, and process water systems. Filtertech equipment used for Optical Lens Generating Coolant Filtration include: